Digital implant planning with prefabricated immediate provisional: A digital workflow example

Read related content:

How digital treatment planning can increase case acceptance

Building a "futureproof" digital workflow

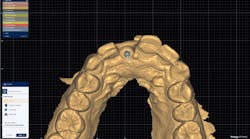

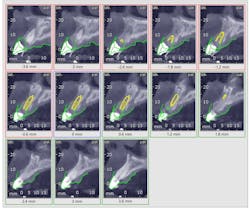

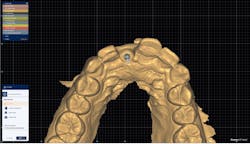

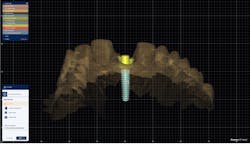

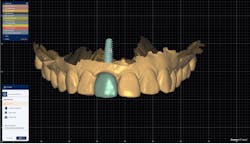

Next, the wizard steps were completed for a screw-retained restoration. After selecting the proper height titanium base, the software then merged the crown wax-up with the titanium base that had been selected. The occlusion and contact were adjusted, and the screw channel was subtracted from the crown. After the implant crown is finalized and merged into a new STL file, the final crown can be manufactured by the method of your choosing. In this case, it was 3D printed out of NextDent C&B MFH composite material on the NextDent 5100 printer. The printed crown was postprocessed according to the manufacturer’s instructions and then bonded to a titanium base using multilink hybrid abutment cement (Ivoclar Vivadent). The crown was then characterized using Optiglaze stains (GC America) and polished.

At surgery the implant was placed fully guided, and the clocking of the hex was aligned with the engraved hex markers on the surgical guide to ensure proper seating of the provisional crown titanium base complex. After implant placement was completed, the crown was seated, and the abutment screw hand-torqued. The screw access was sealed with Teflon tape and composite, and the occlusion was adjusted to ensure no contacts were on the crown. Sutures wereThe benefit of this workflow is reduced chair time and an accurately fitting provisional restoration that is completely premade to sculpt the emergence profile during the healing process. Possible issues that could happen include an improperly aligned implant connection that would prevent correct seating of the crown or poor primary stability of the implant. The latter can be overcome by carefully adjusting the orientation of the implant connection to correct the alignment of the provisional. These potential problems can easily be avoided by adhering to a careful surgical protocol and being mindful of the bone quality while preforming the osteotomy.

Editor's note: This article appeared in the November 2021 print edition of Dental Economics.