Clinical impressions of digital impressions

by Gary M. Radz, DDS

For more on this topic, go to www.dentaleconomics.com and search using the following key words: CAD/CAM, digital dentistry, digital impressions, Dr. Gary M. Radz.

The age of digital dentistry has arrived in full force and is changing the way we all provide dental care. Digital radiographs are becoming the norm. CAD/CAM-created restorations are proving to meet and even exceed expectations. We use CAT scan technology to identify implant placement with accuracy never before thought possible.

Many of us communicate with our laboratory technicians and colleagues on a regular basis via e-mail and/or text messaging. We have automated patient reminder systems to let our patients know when their next appointment is, or to just wish them a happy birthday. We have Web site and search optimization companies to create online presences for our practices. We do our business banking online, and even help our patients get financing online. In short, digital technology has a tremendous impact on all aspects of how we practice dentistry.

In our office, we have incorporated all of the above-mentioned technologies to enhance our practice, improve our efficiency and quality as we build our practice, and provide our patients with better service.

Seeing all the positive effects that digital dentistry has had on our practices, it's time for all dentists to begin to take a serious look at the “next big thing” in the digital world of dentistry — digital impression systems.

Within the past two years, two companies have been working and now distributing machines capable of taking a digital impression and fabricating a working model for the laboratory technician. Cadent and 3M, using very different technologies, have now entered the U.S. dental market with their machines. We are proving that they can compete with conventional impression systems to make lab models that can create restorations equal to or exceeding the quality of conventional techniques.

In my 18 years of dentistry, I've never been so excited about a new technology as I am about the current and future potential of digital impression technology. In August 2008, we began using the Cadent iTero™ impression system, and we have been impressed with its capabilities since the first day.

Let's began by asking, “What is a digital impression system?” With either the 3M or Cadent system, the basics start with capturing an image of a tooth (or teeth) preparation. Using different technology, each system uses a camera to capture the desired image. This image is then electronically transferred to a manufacturing facility which fabricates a working, articulated model. This model is then sent to the lab of choice. From this model, a multitude of different restorations can be fabricated — crowns, bridges, inlays/onlays, and veneers are all possible.

I learned about the development of the 3M Lava™ C.O.S. system, watched demonstrations, and had the opportunity to work with it in a hands-on “countertop” environment. It is an impressive system that, from all my personal observations, will meet and/or exceed the company's advertised expectations.

However, for purposes of this article, my clinical observations and comments are limited to our four-month experience with the Cadent iTero system.

Clinical impressions

Once we decided to bring the iTero (Fig. 1) into our office, our initial concern was the training and learning curve. Cadent provides three days of in-office training. We were training two doctors and two assistants. We sent the trainer home early on the second day because we had the system down! Each doctor and assistant were proficient and comfortable with the system by the third case — the learning curve was that short and easy. The reason for this is because the system is very intuitive. Only a few basic steps must be learned, and the system's voice prompts walk you through most of the procedure.

Fig. 1: Cadent's iTero™ digital impression machine.

The perception in our office is that we are completing our indirect procedures as fast — and probably a little faster — than when we were using conventional impression techniques.

From a cost standpoint, we feel we are about breaking even at this point. If you separate the cost of the machine (which is significant, but will be addressed later), a conventional impression with a stock tray costs $17.37 to $34.10. The iTero models cost $25.

However, the real cost savings are at the delivery appointment. Our experience with delivering our indirect restorations, fabricated using the iTero system, has been nothing short of amazing. We are seeing consistently excellent margins. We attribute this to the fact that we are evaluating our margins on a 19-inch monitor and the dies are being trimmed digitally.

But most impressively, we are spending little, if any, time adjusting occlusion. Before the iTero, we routinely expected to spend five to 10 minutes of the appointment refining the occlusion. With the iTero restorations, we rarely spend more than two minutes. Although we are not putting ourselves on a stopwatch, it's been very noticeable to both the doctors and the assistants.

We have also been impressed by the lack of adjustment needed on second-molar restorations. It used to take a significant amount of time to perfect the occlusion at delivery with second-molar restorations. With the iTero, second-molar restorations require only a few minor adjustments. Our clinical observations are verified by Henkel's 2007 research demonstrating that iTero restorations required 33% less time to adjust the occlusion.

Benefits of digital impressions

Using a digital impression system provides many benefits to your patients and your practice.

1. Digital impressions eliminate the uncomfortable experience of making a physical impression. Taking impressions can be stressful for the doctor and assistant and uncomfortable, stressful, or even traumatic for the patient.

2. Digital impressions are an incredible teaching tool because you can evaluate your preparation (Fig. 2) on a 19-inch monitor. Every day I look at and critique my preparations in an entirely different light. Being able to see a “blown-up” image of my preparations forces me to become better at designing my restorations.

3. The image on the monitor shows you if you have captured all the needed data before sending it to the lab. With a physical impression, we look (usually with loupes on) and evaluate our impressions to be sure they are adequate to send to the lab. But there can be areas that we can't see well, causing us to miss an area that is inadequate. When the impression is displayed on a 19-inch monitor, we can rotate it and see every detail. We know before we send the impression if we need more data. Although we dentists believe we send only perfect impressions to the lab, Dr. Gordon Christensen reported in 2005 that 50% of impressions do not show the entire preparation margin.

Fig. 3: An iTero fabricated working model with removable dyes.

4. The accuracy of the mounting, bite registration, and stability of the dies create a model (Fig. 3) that allows the laboratory technician to fabricate a final restoration that has excellent marginal fit and incredibly accurate occlusion.

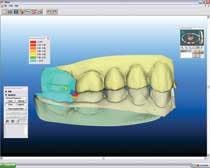

5. Immediate- and long-term benefits are realized by being able to see if proper occlusal reduction has been achieved. Maybe the biggest advantage of the iTero impression system is allowing the dentist to know that adequate occlusal reduction has been created. When the final impression is scanned and the bite registration is obtained, a virtually articulated model of the preparation is visible on the monitor. The system will indicate in color if any areas of inadequate reduction are present (Fig. 4). With this system, it is impossible for a dentist to unknowingly send an insufficiently prepared impression to the lab.

Fig. 4: Areas of red show the need for further occlusal reduction.

The benefits from this information are huge! No longer do we need reduction copings or required reduction of opposing dentition. There is now adequate room to create occlusal anatomy and great esthetics. The long-term benefit is an obvious extension; we should see significant reduction in the frequency of porcelain fractures of our posterior restorations.

6. Because of these reasons, there should be (and has been in our practice) a noticeable reduction in remakes. Because of all the detail that can be seen before the impression is sent, the knowledge of adequate occlusal reduction, and the accuracy of the models, the margin for error has been dramatically decreased.

7. Disinfection of impressions is now a non-issue with a digital system.

8. Recordkeeping. The digital impression can be stored indefinitely. For the dentist that has a basement or garage filled with old models, this will open a whole new world. We are envisioning scanning the patients' preeoperative and postoperative conditions on our larger restorative and/or esthetic cases. We do not intend to create the physical models, but will store this information for legal documentation.

9. Reduction of inventory, streamlining procedures, and going green. We no longer have to keep large amounts of impression materials in the office. We have developed systems to minimize time and maximize the abilities of the iTero unit. Lastly, digital data is thrown away with the “delete” button. The environmental “footprint” of digital impressions is significantly smaller than traditional impression materials. Just think about the volume of used impression materials thrown away daily. Also, with no physical impressions, there is no need for impression trays. That results in a dramatic drop in the use of plastics associated with disposable impression trays. Lastly, we eliminate the need to retake an impression, and we expect a minimization of remakes. Both of these factors will reduce the volume of traditional impression material used.

Disadvantages of digital impressions

The disadvantages of digital impressions are few:

1. Until recently it was not possible to do full-arch impressions. Now, the updated software allows this. However, a full-arch impression taken digitally does take more time than a conventional impression technique. The advantage with the digital scan is that each tooth is scanned individually. This allows for excellent site-by-site tissue management and moisture control, as opposed to traditional impressioning, which requires all tissue around all teeth at the same time.

2. At this time, there is limited ability to use this system for implant impressions. Abutment-level scans are possible, and Cadent indicates they are actively working on fixture-level scanning.

3. Many dentists who look at the iTero unit immediately comment on the large size of the camera head. I was one of them! We have been pleasantly surprised about how little the size of the camera head has been a problem. In four months, we have had only one patient whose anatomy would not allow for the use of the iTero because of the camera size. To date, we have done dozens of second-molar scans without issue. Dentists concerned with the size of the camera head need to watch an experienced dentist or dental assistant take an iTero impression to see that size, in this case, doesn't matter.

4. The camera weight is more an issue than size if proper techniques aren't used. During training, several positioning techniques were taught that, when applied clinically, made the scanning process comfortable for the operator.

5. Cost. This has to be addressed. The initial investment in the machine needs to be considered into the purchasing decision. We believe the real savings is in the indirect costs associated with reduced seating time, fewer remakes, and fewer less-than-ideal impressions and subsequent restorations. These advantages are what makes us feel this technology is a good investment. There is also the almost universal “WOW” factor this technology brings to our patients!

Based on our short but intensive clinical experience with the iTero system, we are convinced that this was a great investment for our practice. As this technology continues to develop, we believe more labs and dentists will embrace it. The potential is very exciting!

Imagine the model and the crown/bridge coping showing up at the same time in the lab for final porcelain application. This is already happening! For some restorations in the near future, the entire unit will be able to be fabricated without a physical model at all! The potential of the technology is very exciting.

In the not too distant future, we believe that digital impressions will be common in many dental practices, embraced in a similar fashion as we have embraced digital radiography. Now is truly an exciting time in dentistry as digital technology becomes the next step forward in our efforts to perfect the art and science of dentistry.

Acknowledgement

Thank you to Danny Wong and Americus Labs/DSG of Jamaica, N.Y., for their support and feedback about this technology.

Editor's Note: References are available upon request.

Dr. Gary Radz maintains a private practice in downtown Denver, Colo. He is an associate clinical professor at the University of Colorado School of Dentistry. Dr. Radz lectures and publishes internationally on materials, technology, and techniques related to cosmetic dental procedures. More information about him is available at www.garyradz.com.

A simple system for indirect procedures

Clinically, we now have a simple, efficient system for our indirect procedures, which saves a lot of time for us and is very comfortable for the patients. Our standard clinical procedure is as follows:

- Cotton roll with small amount of topical anesthetic is placed near the injection site.

- Assistant takes a “triple-tray” impression of the tooth/teeth to be prepared in a fast-setting polyvinyl alginate substitute material (StatusBlue® from Zenith, AlgiNot FS™ from Kerr, Silginat® from Kettenbach).

- After removing the preop impression, the doctor administers local anesthetic.

- The doctor leaves and the assistant scans the opposing arch. During this time (two to three minutes), the local anesthetic has had time to take effect.

- The tooth/teeth are prepared.

- The preop impression is loaded with an automix temporary material (Luxatemp® from Zenith, Venus® Temp C&B from Heraeus Kulzer) and allowed to set for three minutes.

- The temporary is removed and the doctor goes to the lab and trims the provisional restoration.

- The assistant scans the prepared arch and digitally records the bite registration (three to four minutes).

- The doctor returns to the operatory with the trimmed provisional and evaluates the scan of the preparation. If needed, additional scans are requested or, if the scan is acceptable, the doctor gives the approval for it to be electronically sent for model fabrication.

- While the assistant is cementing the temporary, the doctor is completing the electronic lab prescription.